English

Rm 1955,Building 2,No.215,Lianhe North Rd.,Fengxian Dist.Shanghai 201417 China

Views: 0 Author: Matteo Parenti Publish Time: 2023-11-16 Origin: Site

PET and PETG are anything but new in the world of plastic. This family of polymers is practically everywhere in our lives. While it may not be surprising that water bottles, food containers, and soap dispensers are printed with this material, automobile parts, electrical devices, and textiles also depend on PETs. This cheap, lightweight plastic took the world by storm and doesn’t seem to be going anywhere anytime soon.

All this popularity, undoubtedly due to its low cost and great properties, has also piqued the interest of makers and 3D printing enthusiasts. PETG is often the go-to for mid-range temperature and mechanical resistance on a budget, as it’s cheap, readily available, and easy to print.

PET, on the other end, isn’t a commonly used filament in the 3D printing community. Resources on its properties and print settings are few and contradictory, perhaps because PET filament is hard to come by in the first place. The lack of the -G in PET is often misunderstood, yet it makes a huge difference when it comes to printability.

In this article, we’ll cover the key differences between these two materials, as well as shed some light on why they perform differently at the extruder. Stick around to learn more!

PETG is glossy, and sometimes even transparent, but why? (Source: furysamurai72 via Reddit)

PETG is glossy, and sometimes even transparent, but why? (Source: furysamurai72 via Reddit) Let’s start right off the bat with a bit of chemistry. It’s a common misunderstanding that the main difference between PET and PETG is the physical addition of a glycol additive to PET. While glycol is indeed a common plastic additive with plasticizing effects, this is not quite what is happening in the case of PETG.

To make matters a bit more confusing, “glycol” is actually a generic term for a class of structures that have hydroxyl (-OH, oxygen and hydrogen) groups at two ends. So there are many different chemical structures that all can be considered a glycol. However, not all glycols have the same properties, and that’s the key to the PET vs. PETG question.

A basic formula for making polyesters, like PET and PETG, is the combination of acid monomers plus glycol monomers. In the case of PET, the acid is usually DMT (dimethyl terephthalate) and the glycol is ethylene glycol. These two monomers are the building blocks of the final long-chain polymer: polyethylene terephthalate.

For creating PETG, the same monomers are used, except some ethylene glycol (30-60% according to literature) is substituted with a different glycol monomer, CHDM (cyclohexanedimethanol). So it’s not that PETG has significantly more or less glycol than PET, it just has a different type of glycol. Therefore, the -G in PETG represents the chemical modification of the typical PET structure with CHDM glycol units, or “glycol-modified” for short.

So now that we understand the chemical difference between PET and PETG, what does this mean for their physical properties?

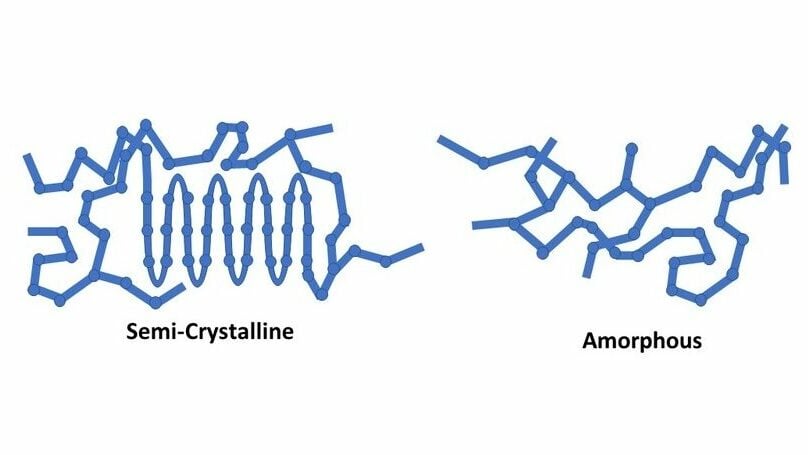

Just a little chain management can go a long way (Source: CKN Knowledge in Practice Centre)

Just a little chain management can go a long way (Source: CKN Knowledge in Practice Centre) The key impact of this glycol modification from a physical standpoint is that semi-crystalline PET gets transformed into amorphous PETG. Let’s quickly review what crystallinity has to do with polymers and why its relevant to 3D printing.

In a few words, amorphous polymers have all their chains arranged randomly, much like a bowl of spaghetti. Semi-crystalline polymers contain regions of crystallinity where chains are highly-ordered and densely packed. This has an enormous impact on material properties.

Semi-crystalline materials are generally more rigid compared to a totally amorphous counterpart, as crystalline regions can function as reinforcement. This holds true for semi-crystalline PET and amorphous PETG. Although the mechanical properties of these two polymers are generally very similar, you can get a little more stretch from PETG.

While cooling, semi-crystalline materials are prone to warping caused by changes in density brought on by the formation of crystalline regions. This means amorphous PETG is much more manageable for 3D printing. Semi-crystalline PET, on the other hand, requires stricter printing and ambient temperatures to prevent distortions.

PET also has a slightly higher working temperature compared to PETG due to its crystalline nature. While this may make it more difficult to print with, PET will hold up better in applications that require some thermal resistance.

You may also notice visual differences between the two materials. The purely random nature of the polymer chains in PETG creates glossy or even transparent filaments. PET, as a mixture of crystalline and non-crystalline regions, will have some haziness.

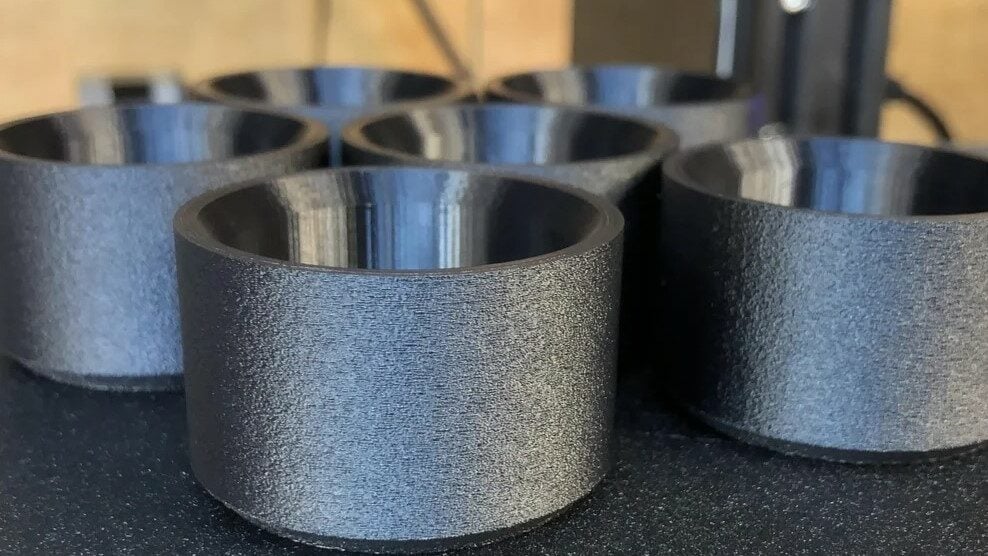

Cura's fuzzy skin setting can mattify the typical PETG shine (Source: tomsloat via Reddit)

Cura's fuzzy skin setting can mattify the typical PETG shine (Source: tomsloat via Reddit) Crystalline structures, like those of PET, don’t play well with extrusion. Crystallization is difficult to control and can begin as soon as the plastic is just a bit too cool. Manufacturers often facilitate extrusion using additives that hinder crystallization. Not to mention that working under well-tuned conditions is a given.

On the other side, glycol modification of PET renders it an amorphous material that can easily be modeled via extrusion, injection molding, and other thermo-forming processes. This is the key to the success of PETG.

From a practical standpoint, there aren’t a lot of differences between the two when it comes to printing parameters. Many users happily report using their PETG temperature profile for PET and having no issues. Although, this may be due to manufacturers formulating with other additives that have a similar crystallization-hindering effect.

Whatever the secret sauce is, most guides and tables put PET and PETG in the same category. So if you do find yourself with some PET filament, the following PETG parameters are a good starting point:

Hot end temperature: 230-260 °C

Print bed: 80-90° C on a textured PEI sheet

Fan speed: 0-50%

Retraction: Slow retraction speed and linear advance enabled

First layers: Slower and hotter to promote adhesion

As always, follow the manufacturer’s specs and recommendations.